Specialty Cleans Markets – Advanced Nodes Drive Growth

In the midst of mounting technical challenges for wet chemical suppliers

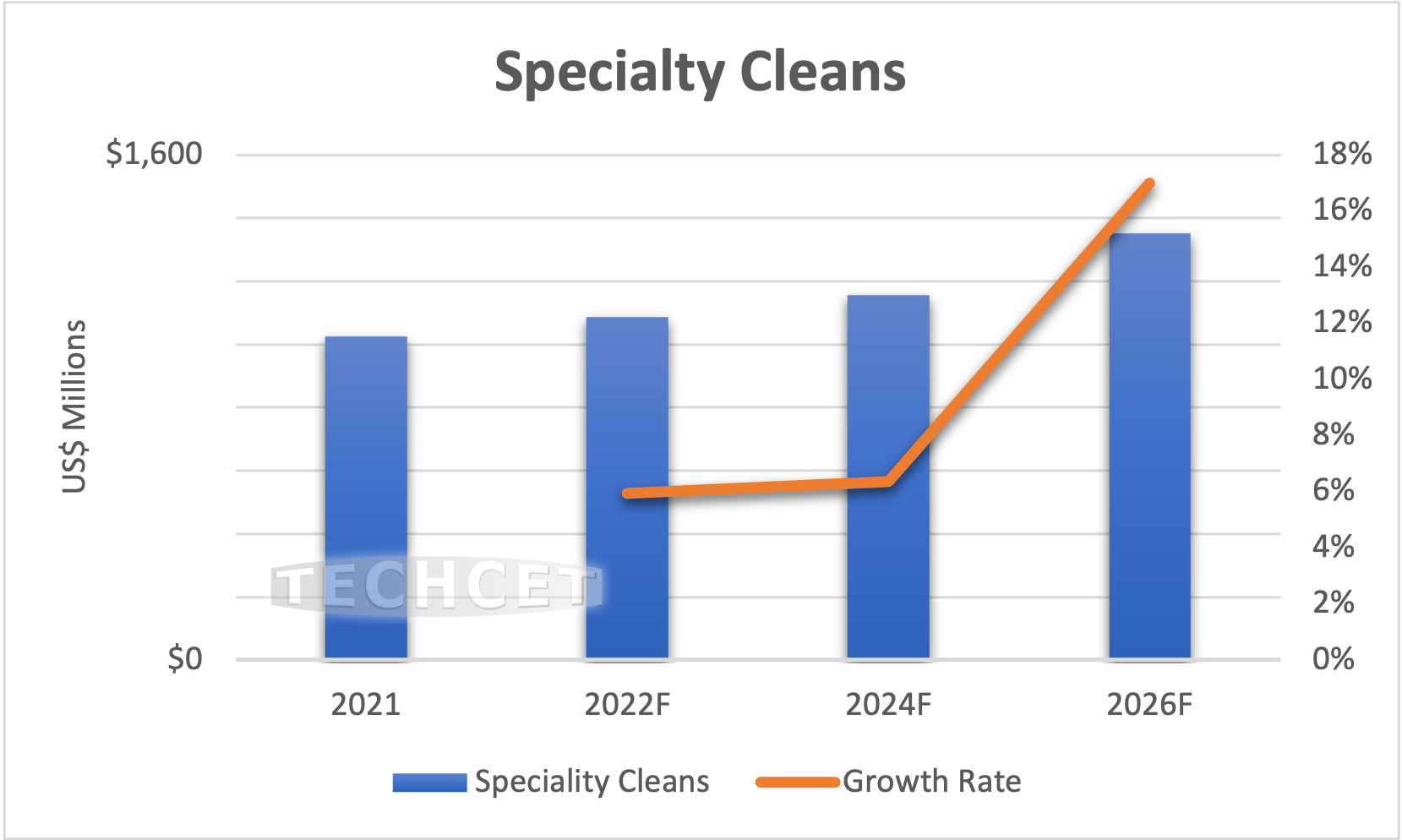

San Diego, CA, June 21, 2022: TECHCET—the electronic materials advisory firm providing business and technology information— announced a large growth forecast for Specialty (Formulated) Clean Chemistries as part of the overall Wet Chemicals outlook through 2026. In 2021, the Specialty Cleans market topped US$1 billion, and it is forecasted to reach US$1.1 billion in 2022. Through the forecasted period, this market will grow at a 6% CAGR, primarily due to increases in process layer, and advanced technology nodes often having multiple cleaning processes per mask step, as highlighted in TECHCET’S newest Wet Chemicals and Specialty Cleans Critical Materials Report™.

Specialty cleans consist of Post Etch Residue Removals (PERR) and post-PCMP (pCMP) cleans, which increasingly require new and advanced formulations to keep pace with new materials, high layer counts, and tighter specifications for particle size. PERR usage has increased with each progressive logic node, while pCMP cleaning requires a chemical solution which can remove residual particles of both slurry and removed material layers.

“Capital investments by the suppliers in the technology are critical to keep pace with leading-edge device process technologies”, states Terry Francis, Director of Technology & Sr. Analyst of TECHCET. “Suppliers that are not investing in advanced formulations are at risk of losing market share in this market.”

Volumes of PERR dramatically increase for advanced Logic and 3DNAND device production. This is driven by the increased number of mask steps, the increased layers in 3DNAND, and the number of Etch-Trim steps. Extreme Ultraviolet Lithography (EUVL) is helpful in leveling the number of mask steps and changing the PERR Chemistry, but it is currently at a low volume of wafer starts across the industry.

PERR is a very application specific space that requires cleans formulated specifically for the process. This is mainly because of the number of sensitivities to the chemicals along with galvanic corrosion issues. Because of this, this market requires both past knowledge of PERR cleaning, alongside adjustments of formulations per device level and surfaces exposed.

pCMP Cleans will also continue to be played as custom formulations and added value area protect suppliers’ margins and market position. Cleaning solutions must not damage remaining and exposed wafer layers, including dielectric films and copper.

Francis also noted, “because of these technical challenges, the Specialty Cleans market is not easy to enter for a supplier without a close partnership with the device maker.”

For more details on the Wet Chemicals & Specialty Cleans market segments, or for TECHCET consulting services on specialty cleans go to: https://techcet.com/product/specialty-cleaning-chemicals/.

ABOUT TECHCET: TECHCET CA LLC is an advisory services firm focused on process materials supply-chains, electronic materials business, and materials market analysis for the semiconductor, display, solar/PV, and LED industries. Since 2000, the company has been responsible for producing the Critical Material Reports™, covering silicon wafers, semiconductor gases, wet chemicals, CMP consumables, Photoresists, and ALD/CVD Precursors. The Critical Materials Council (CMC) of semiconductor fabricators is a business service offered by TECHCET, and includes materials supplier Associate Members. For additional information about reports, market briefings, CMC membership, or custom consulting please contact info@cmcfabs.org, +1-480-332-8336, or go to www.techcet.com.