Semiconductor Grade IPA Supply Impacted by COVID-19

San Diego, CA – December 21, 2020: The Critical Materials Council (CMC) of semiconductor fabricators & suppliers joint-meeting in December focused on disruptions in the global supply-chain for high-purity acids and solvents due to the boom-and-bust business of oil refining. Due to COVID-19 pandemic travel restrictions reducing passenger travel, there has been a well-documented reduction in demand for oil and gasoline that has led to the idling of some petroleum refineries. Much of the world’s industrial chemical supply starts with petroleum feedstocks, so when refineries stop running they stop supplying the world with raw material.

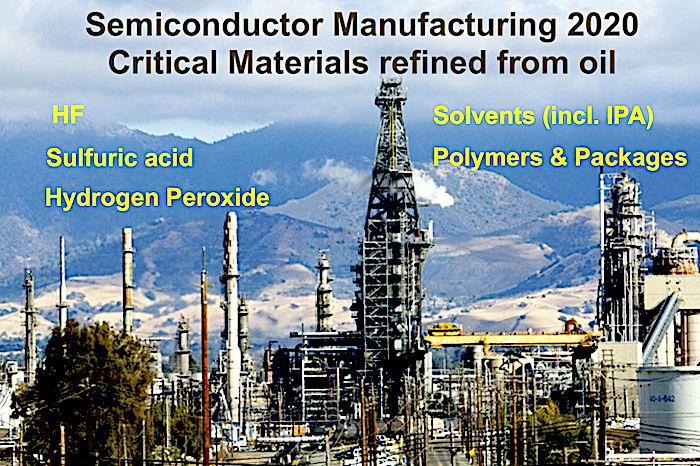

As shown in the Figure, wet chemicals including sulfuric acid, hydrogen peroxide, and iso-propyl alcohol (IPA) are typically engineered these days using feedstock from oil refining derivatives. During the December CMC Joint Session of chip fabricators and suppliers, a representative from Cargill Corporation (annual revenues ~US$114B) presented information on sustainable bio-based feedstocks that can replace petrochemicals in the global supply chain.

TECHCET material demand models estimate that 2020 worldwide semiconductor device fabrication will use and dispose of the following:

• 291 million kg of sulfuric acid or 760,000 55-gallon drums,

• 202 million kg of hydrogen peroxide or 857,000 55-gallon drums, and

• 20 million kg of IPA or 122,000 55-gallon drums.

Earlier this year, TECHCET raised “cautionary flags” at CMC meetings to watch for 2H20 shortages of IPA and sulfuric acid, as also detailed in quarterly updates to TECHCET’s Wet Chemicals & Specialty Cleans analysis. Governments around the world have mandated that some of the industrial IPA supply-chain be re-directed to healthcare and consumer distribution to combat the COVID virus, increasing overall demand. French IPA producer Seqens had to declare force majeure on its IPA plant in Peage, Roussillon from March to July of this year, and with a nameplate capacity of 70k tons/year that plant represents >12% of total European capacity. Despite recent news of vaccines, the pandemic continues to disrupt the chemistry value-chain.

During the December 8, 2020, CMC meeting, Fab Members from around the world reported tightening supply of high-purity solvents in general. Within the solvent category, there is now serious concern that a shortage in high-purity IPA is looming just over the business horizon. To join the CMC for 2021 meetings in virtual-space to anticipate and mitigate such supply-chain disruptions, or for custom consulting please contact us – Email, +1-480-332-8336.

For more information on solvents, wet chemicals, and other critical materials used for semiconductor production: TECHCET Reports